FP Seat Back Endurance Tester-Front Push Type

其他信息

| Brand Name | Wecantester |

|---|---|

| Place of Origin | |

| Standards | BIFMA X5.4-2020, BIFMAX 5.1-2017, QB/T 2280-2016 |

Product Details

| Function | 1. Seat and backrest durability testing machine conforming to GB BIFMA standard; 2. Closed-loop control. The output end of the cylinder is installed with an American fatigue-grade tension pressure sensor, and the air pressure control of the cylinder adopts the control of the Japanese SMC gas-electric proportional valve, which forms a closed-loop real-time control with PLC; 3. Multifunctional. The output force of the cylinder (used for the durability test of the backrest) or the output displacement (used for the durability test of the rear tilt mechanism of the chair chassis) can be selected and controlled through the touch screen; 4. Use BIFMA-compliant backrest loading pads for loading. When unloading, the loading pads are separated from the chair backrest, and the backrest rebounds to the initial position by its own structure. Compared with the back-pull type, the forward-pull type is closer to the simulated seat use state. Or more standard. (Our opinion) Therefore, it is recommended that the laboratory use; 5. Simple clamping structure, all operations can be realized by one person without any tool assistance; 6. The cylinder (power component) can be slid left and right to adjust the backrest lateral force endurance test required by BIFMA. | ||||

| topic | standard | chapter | Chapter title | ||

| standard | QB/T 2280-2016 | 6.6.9.1 | Back and forth durability (suitable forItype office chair) | ||

| BIFMA X5.1-2017 | 15 | Backrest Durability Test | |||

| BIFMA X5.4-2020 | 7 | Backrest Durability Test – Horizontal – Cyclic(single seat) | |||

| parameter | 1.Cylinder: output force30~180Kilogram force; Max stroke:500 mm; 2.count:6 Bit; with stop/power off memory function/avoid loss of test data; 3.speed:10 ~ 25 times/minute adjustable; 4.Sample: The maximum allowable installation size is less than850*850 mm; 5.Dimensions:1440*1400*1780mm,448 Kilogram; 6.Air source: Air pressure:>0.5MPa;flow:2800 L/min; air source needs to be filtered and dried. 7.power supply:220VAC, 2A | ||||

| picture |  |

||||

| Features | 1. Suitable for multi-standard seat back and seat surface durability testing requirements. 2.useSMC The shaft core is not driven by the cylinder, and the cylinder output force control mode or displacement control mode can be selected to work. 3. The cylinder loading assembly can manually adjust the left and right and front and rear positions along the frame, and the electric drive beam can adjust the position up and down. 4. Simple clamping structure design without any special auxiliary tools. 5.Universal foot pad equipment, so that the minimum distance between the equipment and the ground is greater than80mm for easy adjustment of equipment level and forklift handling. | ||||

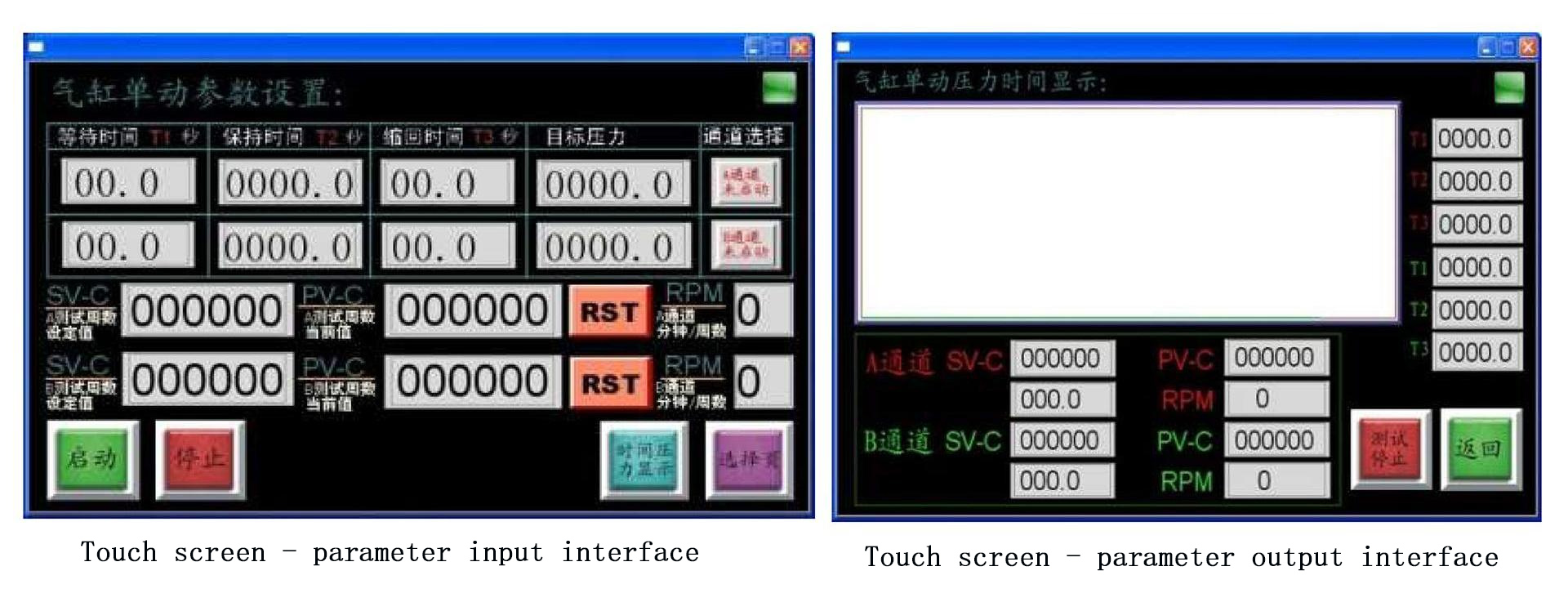

| control | 1. Touch screen to input test parameters and output test results. 2. It is controlled by the single-chip microcomputer developed by our factory. Optionally control the output force or displacement of the cylinder, with tracking and display force-time curve, countdown for each loading section, overload output alarm, etc. 3. In the selected cylinder output force control mode, the force is closed-loop control. That is: only when the current value of the loading force reaches the set value 95%(can be modified in the background) to trigger the delay, and can keep the current value at the set value±3%fluctuations within (standard to ask for soil 5%) o 4. In Select Cylinder Output Position mode, displacement is controlled by moving a magnetic sensor attached to the cylinder surface. 5.The system has stop/power-off memory function, low pressure detection function and breakpoint shutdown function. | ||||

| important accessories | Accessory name | brand | quantity | Origin | use/function |

| touch screen | Wei Luntong | 1piece | China | HMI | |

| MCU | Wecan (factory) | 1set | China | Core originals, program storage and operation | |

| Gas-electric proportional valve | SMC | 1piece | Japan | Convert electrical signals to air pressure signals | |

| Pull pressure sensor | Ailogics (USA) | 1piece | China | Convert the tensile force value into an electrical signal | |

| signal transmitter | Wecan (factory) | 1piece | China | electrical signal processing | |

| cylinder | SMC | 1piece | Hongkong | Actuator, output pressure | |

| Standard accessories | Numbering | name | quantity | use | |

| WT-BFM-06 | Seat surface load code assembly | 1set(240lb) | Simulate seat surface loads | ||

| WT-BFM-03-FP | BIFMASeat Back Loading Pad – Back Push | 1set | Seat Back Clamping Fixture | ||

| WT-FIX-03 | chair legsLType platen | 1set | Fixed office chair legs | ||

| WT-FIX-02 | Chair rear foot high baffle | 2piece | Block (fix) seat position | ||

| WT-FIX-01 | Anti-rotation adjustable bezel | 2set | Block and place the sample under test for rotation | ||

| Non-standard accessories | WT-FIX-06 | Four-legged stool fixing clamp | 1set | Sichuan seat (stool) fixture | |