Mattress Mechanical Properties Comprehensive Testing Machine

其他信息

| Brand Name | Wecantester |

|---|---|

| Place of Origin | |

| Standards | QB/T 1952.2-2011 GB/T 26706-2011 EN 1957:2012 ASTM F1566-14 |

Product Details

WT-BSE-38Mattress Mechanical Properties Comprehensive Testing Machine

| topic | standard | chapter | Chapter title |

| standard | QB/T 1952.2-2011 | 6.2&6.3&6.15& appendixA | Test Set-up, Dimensional Deviation (Test), Durability, Evaluation of Soft and Hard Performance of Spring Soft Mattress Surfaces |

| GB/T 26706-2011 | 6.7&appendixA | Durability Test & Mattress Durability Test Method | |

| EN1957:2012 | Furniture – Beds and mattresses -Test methods for the determination of functional characteristics and assessment criteria | ||

| ASTM F1566-14 | Standard Test Methods for Evaluation of Innersprings, Boxsprings, Mattresses or Mattress Sets – (Need to replace the stick) | ||

| Features | 1.Powerful automatic comprehensive testing machine, consisting of up to3 Set of servo loading system. 2. Compliant with a number of relevant international standards, covering all mechanical testing requirements of mattresses. 3.According to the requirements of standard test procedures, our company has developed special operating software. Option to execute a test individually or select all tests item one Sub-clamping and setup are fully automatic and a graphically described report of the test results is given. 4.All parameter settings and test results have automatic memory function of stop/power off to avoid loss of tested data. | |||||

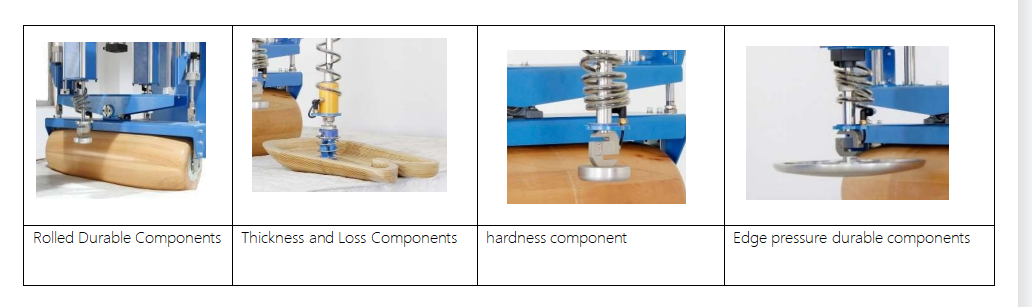

| Functional component parameters | component name | Rolled Durable Components | Thickness and Loss Components | Soft and Hard Components | Edge Compression Durable Components | |

| Component Control System | Servo Control | Precision pressure regulator | ||||

| vertical loading height | 30-450mm | 0-370mm | 0-370mm | 10-350mm | ||

| Horizontal loading stroke | ±250mm | ±125mm | ±125mm | 0-600mm | ||

| Loading displacement accuracy | ±0.5mm | |||||

| Loading force, accuracy (Newton) | 1400±7 N(standard requirement) | 0-1500N±0.1N | 0-1500N±0.1N | 300-1500Nz ±3%(standard requirement1000N) | ||

| Loading speed can be set | 10-20times/min | 50-1000mm/min | 8-20times/min | |||

| Standard requires loading speed | 16±2times/min | 100±20mm/min | 90±5mm/min | 12±2times/min | ||

| load power, brand | Panasonic AC Servo Motor | cylinder£MC | ||||

| Transmission system | TBILinear drive | The shaft core does not rotate the cylinder | ||||

| sensor | no need | Keli | power transmission | |||

| Device parameters | Effective work surface size | 22*2.4Meter; | ||||

| Main body dimensions, net weight | 2680*2410*2030mm,893Kilogram; | |||||

| Dimensions, net weight | 600*540*1200mm28.8kg (excluding computer); | |||||

| Gas source | >0.5MPa;flow:2800L/min; air source needs to be filtered and dried; | |||||

| power supply | AC220Simplex50/60HZ, 1600Wo | |||||

| Standard accessories | Numbering | name | quantity | use | ||

| WT-FIX-08 | brand computer | 1 | Test parameter input and output | |||

| WT-FIX-10 | Simple computer console | 1 | Placing computers and peripherals | |||

| WT-BSE-38+A01 | Mattress Firmness Loading Pad | 1 | QB/T 1952.2-2011 A.2.1 | |||

| WT-BSE-38+A02 | Mattress Thickness Test Loading Pad | 1 | QB/T 1952.2-2011 6.2.5 | |||

| WT-BSE-38+A03 | Rollers conforming to national and European standards | 1 | QB/T 1952.2-2011 6.2.4 | |||

| WT-BSE-38+A04 | mattress positioning baffle | 2 | QB/T 1952.2-2011 6.2.1 | |||

| WT-BSE-01 | Seat loading pad | 1 | QB/T 1952.2-2011 C.1 | |||

| Non-standard accessories | WT-BSE-38+B01 | mattress side2NTest Fixture | 1 | QB/T 1952.2:2013 6.311 | ||

| WT-BSE-38+B02 | American Standard Mattress and Cunjiu Testing Machine – Hexagonal Roller | 1 | ASTM F1566-14 | |||

| WT-GBF-06 | Furniture testing aluminum alloy square tube | 1 | 1952.2:2013 6.2.3 | |||