Seat Armrest Testing Machine

其他信息

| Brand Name | Wecantester |

|---|---|

| Place of Origin | |

| Standards | BIFMA X5.4-2020, BIFMAX 5.1-2017, BS EN1728:2012, GB/T 10357.3-2013, ISO7173:1989 |

Product Details

| topic | standard | chapter | Chapter title | |||

| standard | GB/T 10357.3-2013 | 4.5&4.6 | Lateral & Vertical Downward Static Load Test of Armrest and Pillow | |||

| 4.9 | Handrail Durability Test | |||||

| BIFMA X5.1-2017 | 10.4 | Front Corner Load-Ease Test – Cyclic oneOff-center | ||||

| 20 | Arm Durability Test -Cyclic | |||||

| 24 | Structural Durability Test -Cyclic | |||||

| BIFMA X5.4-2020 | 13 | Arm Durability Test for Single Seat Units -Cyclic | ||||

| BS EN1728:2012 | 5.11&6.20&7.10&8.7 | Arm rest durability test | ||||

| 6.10&6.11&7.7&8.6 | Arm rest sideways & downwards static load test | |||||

| 6.18 | Seat front edge durability test | |||||

| 7.5&7.6 | Arm rest downward static load test onecentral & front | |||||

| ISO7173:1989 | 7.3&7.4 | Arm and wing sideways & downwards static load | ||||

| parameter | 1.Loading cylinder diameter50mm, stroke250mm, adjustable cylinder output force range:30-100 kilogram force. 2.The distance from the pivot point of the adjustable cylinder installation to the armrest:400-800mm (standard requirements600 mm). 3.The height range of the electric adjustment beam from the test platform:680-1380mm, adjustable test speed:10 ~ 25 times/minute adjustable. 4.Cumulative number:6 Bit; with stop/power-off memory function to avoid loss of test data. 5.Dimensions:2340*980*1970mm, net weight:440 Kilogram. 6.power supply:220VAC, 2A,Air source: air pressure greater than0.5MPazThe air source needs to be filtered and dried. | |||||

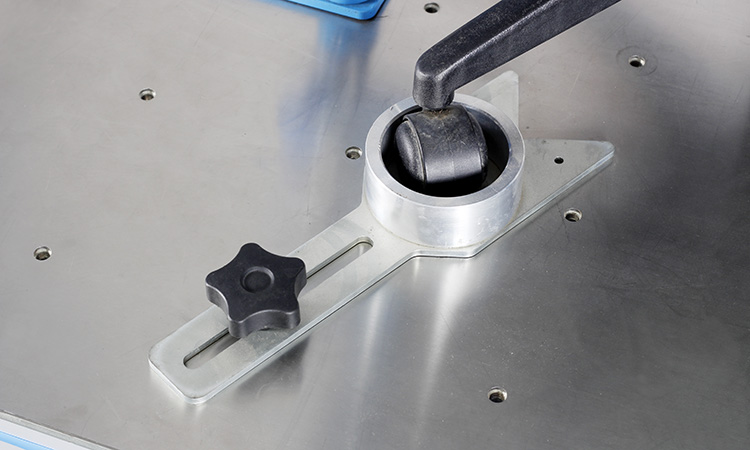

| Features | 1.Suitable for a variety of standard seat armrest testing Require. 2.Adjust the height of the beam electrically, so that the distance between the rotating fulcrum of the cylinder and the armrest to be tested is600 mm (standard requirement). 3.During the handrail durability test, the initial10 The inclined loading angle is confirmed by the baffle, and the cylinder follows the deformation of the handrail during loading (standard requirement). 4.Simple clamping structure design, all operations can be completed quickly by one person without any tool assistance. | |||||

| control | 1. It is controlled by the single-chip microcomputer developed by our factory, and the output force or displacement of the cylinder can be optionally controlled. 2. Touch screen input parameters and output test results, track and display force-time curve, overload output alarm, etc. 3.In the selected cylinder output force control mode, the force is closed-loop control. That is: when the current value of the loading force reaches the set value 95%(Background setting) Trigger delay and keep current value at set value±3%Internal fluctuations (standard requirements are ±5%) o 4. In Select Cylinder Output Position mode, displacement is controlled by moving a magnetic sensor attached to the cylinder surface. 5.The system has a stop/power-off memory function’LowAir pressure detection function and breakpoint shutdown function. | |||||

| important accessories | Accessory name | brand | quantity | Origin | use/function | |

| touch screen | Wei Luntong | 1piece | China | HMI | ||

| MCU | Wecan (factory) | 1set | China | Core originals, program storage and operation | ||

| Gas-electric proportional valve | SMC | 2piece | Japan | Convert electrical signals to air pressure signals | ||

| Pull pressure sensor | Ailogics(U.S) | 2piece | China | Convert the tensile force value into an electrical signal | ||

| signal transmitter | Wecan (factory) | 2piece | China | electrical signal processing | ||

| cylinder | AirTAC | 2piece | China | Actuator, output pressure | ||

| Standard accessories | Numbering | name | quantity | use | ||

| WT-BSE-16+A01 | American Standard Handrail Durability Test Loading Fixture | 2piece | Simulate manual loading | |||

| WT-BSE-16+A02 | European standard handrail durability test loading fixture | 2piece | Simulate manual loading | |||

| WT-BSE-03 | Little Butt Loading Pad | 2piece | Seat Surface Alternate Loading Application | |||

| WT-FIX-01 | Anti-rotation adjustable bezel | 2set | Prevents horizontal movement of the sample | |||

| Non-standard accessories | WT-FIX-06 | Four-legged stool fixing clamp | 1set | IIISeat-like (stool) fixture | ||

| WT-BSE-16+B01 | GBHandrail Durable Loading Fixture | 1set | Simulate manual loading | |||