Seat Surface Impact Tester

其他信息

| Brand Name | Wecantester |

|---|---|

| Place of Origin | |

| Standards | BIFMA X5.4-2020, BIFMA X5.9-2019, BIFMAX 5.1-2017, EN1728:2012, EN1730:2012, QB/T 2280-2016 |

Product Details

|

|||

| topic | Standard | chapter | Chapter title |

| standard | QB/T 2280-2016 | 6.6.2 | Seat impact |

| 6.6.12.1 | Seat reciprocating impact durability | ||

| BIFMA X5.1-2017 | 7 | Drop Test -Dynamic | |

| 10.3 | Impact Test | ||

| BIFMA X5.4-2020 | 14 | Seating Durability Tests -Cyclic | |

| 15 | Drop Test -Dynamic | ||

| BIFMA X5.9-2019 | 7.2 | Drop Test – Dynamic -for Units with Seat Surfaces | |

| 7.3 | Durability Test for Units with Seating Surfaces oneCyclic Impact | ||

| EN1728:2012 | 6.24 | Seat impact test | |

| 8.8 | Impact test | ||

| EN1730:2012 | 6.6.3 | Vertical impact test for all other table tops | |

| control | 1. PLC control, input test parameters and output test results through touch screen.

2. Switch between manual impact or automatic impact, and impact or static pressure function by touching the keys on the touch screen; 3. The system automatically calculates and displays the loading speed; 4. The system has a stop/power-off memory function to avoid loss of test data; 5. The system has the function of breakpoint detection and automatic shutdown; 6. 6 -digit counter records the number of loading times, and the accumulated number can be cleared at any time; the accumulated reset touch button has the function of preventing misoperation. |

||||

| Features | 1. It adopts the function of electromagnet attracting iron at low position to get electricity and pull in, and high-position power off to release the function to do free fall impact movement.

2. Optional single manual and multiple continuous automatic shock function; optional shock or slow loading function. 3. Adopt electric synchronously driven trapezoidal screw (self-locking at any position) to adjust the height of the beam for installing the impact component,’ 4. Universal foot pad equipment, so that the minimum distance between the equipment and the ground is greater than 80 mm, which is convenient for adjusting the level of the equipment and forklift handling; |

||||

| parameter | 1. Rated lifting weight: 180 kg ( 400 lbs) (customized);

2. Rated maximum impact stroke: 300 mm (customized upon request); 3. Height of adjustable impact sandbag from test platform: mm;Mainframe: 1440*980*1960mm , split control: 350*300*800mm , whole machine net weight: 577kg ; 4. Air source: air pressure > 0.5MPa; flow rate 2800 liters/min; air source needs to be filtered and dried. 5. Power: 220VAC, 5A. |

||||

| important accessories | Accessory name | brand | quantity |

Origin |

use/function |

| touch screen | Wei Luntong | 1piece | China | HMI | |

| MCU | Wecan

(Our factory) |

1 set |

China | Core originals, program storage and operation | |

| Electromagnetic attraction | Qiandai | 1piece | China | Lift and release the impact sand bag | |

| cylinder | SMC | 1piece | China | Actuator, output pressure | |

| Standard accessories | Numbering | name | quantity | use | |

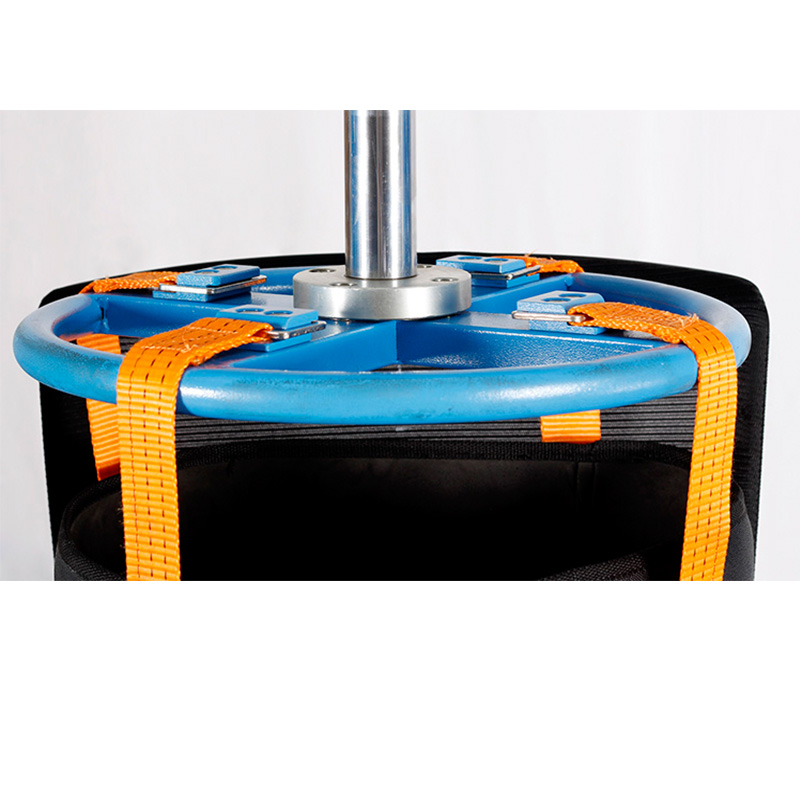

| WT-BFM-02-WT | 16-inchdiameter impact test sand bag | 1 piece | standard requirement | ||

| WT-BFM-04 | Standard weight sand bag | 300 lbs | counterweight | ||

| WT-BSE-02-02 | Standard stop * font | 5 sets | Fix the sample to be tested | ||

| WT-FIX-01 | Anti-rotation adjustable bezel | 2 sets | Prevents rotation of the sample under test | ||

| WT-BFM-11+A01 | Impactheight detection base | 1 set | Check drop height | ||

| WT-BFM-11+A04 | Breakpoint Shutdown Switch Device | 1 set | Detect breakpoint and output stop signal | ||

| WT-BFM-11+A05 | skid block | 2 pieces | Support and positioning equipment | ||

| Non-standard accessories | WT-BFM-11 + B01 | Countertop Expansion Standalone Platform | 1 set | Auxiliary support for large-sized products, such as sofas | |

| purchase reference | 1. All standards require that the impact test must be a free fall of an impact object (such as a sand bag (WT-BFM-02 seat impact sand bag) or impact head (WT-BSE-11 seat impact device) on the sample being tested. sloppy.”

2. Different standards have different interpretations when defining the drop height, and some are vague. Please pay attention to the interpretation standards. |

||||