Single-seat seat-back combined testing machine

其他信息

| Brand Name | Wecantester |

|---|---|

| Place of Origin | |

| Standards | BS EN1728:2012, GB/T 10357.3-2013, ISO 7173-1989, QB/T 2280-2016 |

Product Details

|

|||

| topic | standard | chapter | Chapter title |

| standard | GB/T 10357.3-2013 | 4.3 | Seat surface and seat back static load test |

| 4.7&4.8 | Seat Surface and Seat Back Durability Test | ||

| QB/T 2280-2016 | 6.6.3 & 6.6.8 | Seat Surface, Seat Back Static Load & Durability | |

| BS EN1728:2012 | 6.4&7.3 | Seat static load and back static load test | |

| 6.5 | Seat Front Edge Static Load | ||

| 6.17&7.9 | Combined seat and back durability test | ||

| ISO 7173-1989 | 7.5&7.6 | Seat & Back fatigue test | |

| parameter | 1.Seat surface double cylinder loading, cylinder50*250-Smm, output force50-200 kilogram force. 2.Backrest Single Cylinder Loading / Cylinder50*250-Smm, attachment force30-100 kilogram force. 3.The height range of the electric adjustment beam from the test platform:680-1380 mm. 4.Adjustable test speed:10~25 times/minute adjustable. 5.count:6 Bit; with stop/power-off memory function to avoid loss of test data. 6.Dimensions:980*1420*1960mm, net weight:370 Kilogram. 7.Air source: air pressure greater than0.5MPa,flow greater than1000 L/min, the air source needs to be filtered and dried. 8.power supply:220VAC, 2A.(must be grounded). | ||||

| Features | 1.This product is specially designed for the joint test of the seat and back of the single seat seat of the European standard and the national standard. 2.Electrically adjust the height of the beam, so that the seat surface is loaded and coveredN00-N00mm height. 3.Vertical Loading Cylinder Assembly Mounting Free Horizontal Slide”base”up, adjustable left and right offset±100mm; automatically adjusts when the backrest is loadedThe fore-and-aft position of the section and maintain the vertical loading state. 4.Backrest loading cylinder with adjustable tilt angle0-45degree, adjustable left and right offset±50mm. SatisfyBSEN 1728:2012 7.9For chair backsCombined loading test pairFH, CB, JEA combination of points loads the test mode. (standard requirement) 5.Universal foot pad equipment,Make the minimum distance between the equipment and the ground greater than80mm for easy adjustment of equipment level and forklift handling. 6.Simple clamping structure design/All operations can be completed quickly by one person without any tool assistance. | ||||

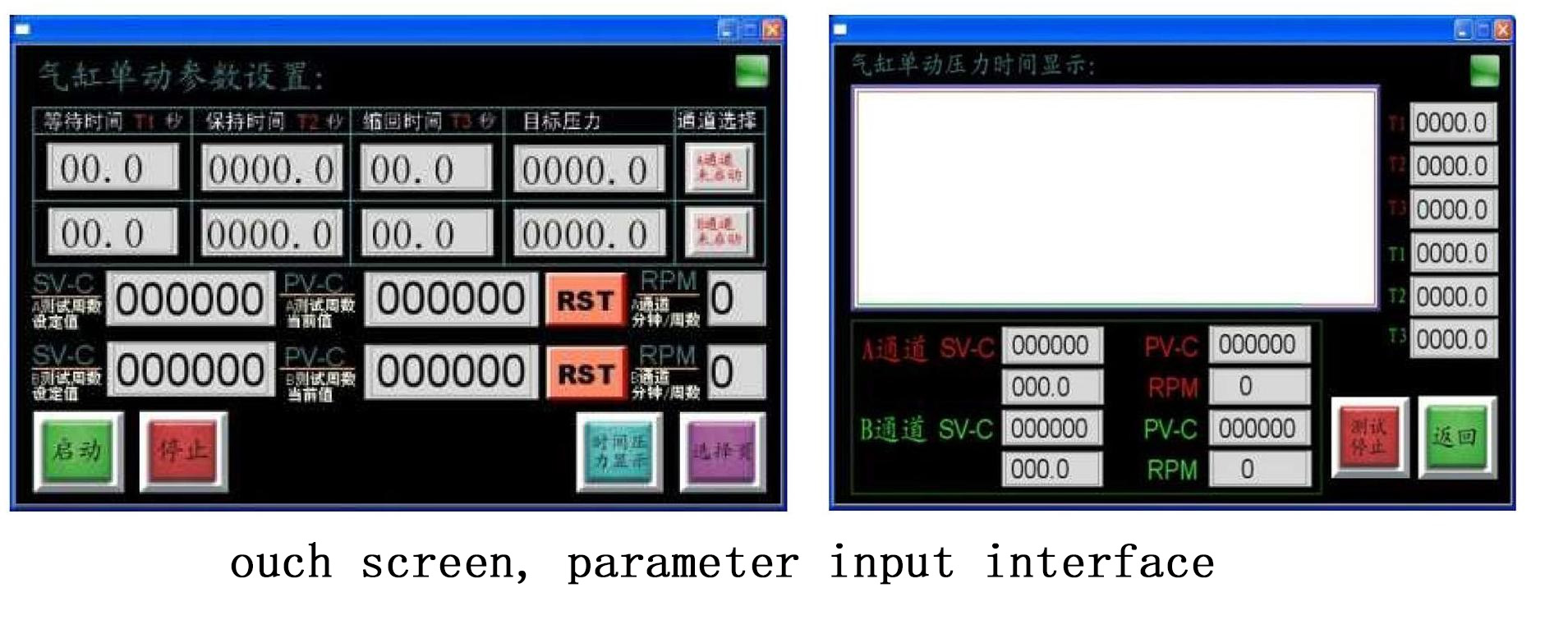

| control | 1. Touch screen to input test parameters and output test results. 2.It is controlled by the single-chip microcomputer developed by our factory. Optionally control the output force or displacement of the cylinder, with tracking and display force-time curve, countdown for each loading segment, overload output alarm, etc. 3.In the selected cylinder input force control mode, the force is closed-loop control. That is: only when the current value of the loading force reaches the set value 95%(can be modified in the background) to trigger the delay, and can keep the current value at the set value±3%fluctuations within. (The standard requirement is ±5%) 4. In Select Cylinder Output Position mode, displacement is controlled by moving a magnetic sensor attached to the cylinder surface. 5.The system has stop/power-off memory function, low pressure detection function and breakpoint shutdown function. | ||||

| control | 1. The two-channel pneumatic closed-loop single-chip control system developed by our factory is adopted. 2. The pneumatic closed-loop control of each channel includes: pull pressure sensor, signal transmitter, single-chip microcomputer, gas-electric proportional valve, and cylinder. 3.The system has a force-time curve tracking display function, a stop/power off memory function, a breakpoint shutdown function, and a low pressure detection function. 4.You can choose to set two groups of cylinders in synchronous or asynchronous working mode, and you can choose to control the cylinder output control force or control displacement working mode. | ||||

| important accessories | Accessory name | brand | Origin | quantity | use/function |

| touch screen | Wei Luntong | China | 1piece | HMI | |

| MCU | Wecan

(Our factory) |

China | 1set | Core originals, program storage and operation | |

| Gas-electric proportional valve | SMC | Japan | 2piece | Convert electrical signals to air pressure signals | |

| Pull pressure sensor | Ailogics(U.S) | China | 2piece | Convert the tensile force value into an electrical signal | |

| signal transmitter | Wecan

(Our factory) |

China | 2piece | electrical signal processing | |

| cylinder | AirTAC | China | 3piece | Actuator, output pressure | |

| Standard accessories | Numbering | name | quantity | use | |

| WT-BSE-01-A | Big Butt Loading Pad (Hardwood) | 1piece | Seat loading | ||

| WT-BSE-05-FP | Seat Back Loading Pad | 1piece | backrest loading | ||

| WT-BSE-02-01 | Standard stop-foot cup type | 5piece | Chair Specimen Fixing | ||

| WT-FIX-01 | Anti-rotation adjustable bezel | 2set | Prevents horizontal movement of the sample | ||

| Non-standard accessories | WT-BSE-03 | Little Butt Loading Pad | 1piece | front corner loading | |